The World’s First 3D Printed Plane Has Landed

Since 3D printing is becoming more widely available we have seen some amazing ideas come to life. From fashion, food, art and prosthetic limbs but now one company has made the world’s first 3d printed aeroplane.

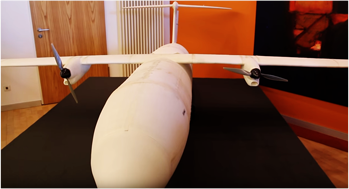

THOR the world’s first 3D printed Drone by European company, Airbus. Revelling there creation at the 2016 ILA Berlin air show. THOR which Symbolizes ‘Test of High-tech Objectives in Reality’ is a much smaller than the planes we are used to seeing weighing in at 46 pounds (21 kilograms) and only 13 feet in length.

How 3D Printing Helps Construction

The advantage to 3D printing is that tools are no longer required for the construction of the aircraft and that the printed parts and be up to 50% lighter than if they were built using the old techniques, And on top on that there almost no manufacturing waste

The initial idea behind THOR was to test what’s possible within the realm of technology and trying to cut down the manufacturing time it takes to create not just parts of an aircraft but the entire system

90% of the structural components where 3D printed just leaving the electrical components which are crafted from a substance called polyamide, using 3D printing to make the fundamental parts of the drone saves time, money and fuel.

If THOR was to take off and come crashing back down to the ground a couple of minutes in to the flight, it wouldn’t cost a lot of for the 3D printed aeroplane to be replaced nor would it take a lot of time to print another one.

3D Printed Planes in Flight

The Drone flies smoothly and is very stable, THOR's initial flight took place in November 2015 the mini aircraft has been continuing test flights ever since. The first test flight was just to see how well THOR could fly but now Airbus are generating data on aspects of the flight like altitude, speed and acceleration in a turn.

Airbus are generating data on aspects of the flight like altitude, speed and acceleration in a turn.

Future 3D printed planes are already in production with the idea to allow for greater flexibility in airframe and structural testing. For example the next version of THOR will boast interchangeable wings, including a metallic aluminium wing, a flexible wing printed with carbon-fiber and a concept hexagonal wing which delivers structural support from its honeycomb design.

Once wing testing is finished the THOR project will focus on AI (artificial intelligence) Working with Airbus Defence and other sections of the Airbus Corporation. The idea is that the THOR aircraft will be able to land completely on its own, assessing obstacles on runway and able to make an independent decision on whether it’s safe for a plane to land on its own without help from any ground support.

Both Airbus and their competitor Boeing are now using 3D printing to makes parts for their planes such as B787 Dreamliner and the A350 XWB, which has over 1,000 3D printed parts on board in a range on materials.

The Future of 3D Printing in Industries

Airbus interested in testing out new material properties that can only be explored through 3D printing.

In the Future 3D printing will allow engineers to design new structures that just aren’t possible with previously used manufacturing techniques. We could start to see structures with a lot of inspiration taken from biological objects, the hulls of the future planes could be like giant ribcages, with the sections in-between with a leaf like structure.

It is also in strong belief that by 2030 that the spare parts for aircraft will be able to be printed in the directly in the airports

I don’t think we will be seeing any commercial planes being completely 3D printed for a while yet, but Airbus has taken as massive lead forward to help 3D printing take off!

Here at Internet-ink we stock a range of 3D Printer filament, Ink cartridges, Toner Cartridges and a wide range of Pens!